Everybody has experienced traffic of some sort. Whether it is a vehicle accident or a mudslide stopping traffic, delays are bound to happen. When the inevitable delay occurs, traffic backs up and can even cause more accidents, which then create more and longer delays. These accidents can be incredibly dangerous as the emergency services will have a more challenging time getting to them due to the amount of backed up traffic. This is where queue warning systems come into play.

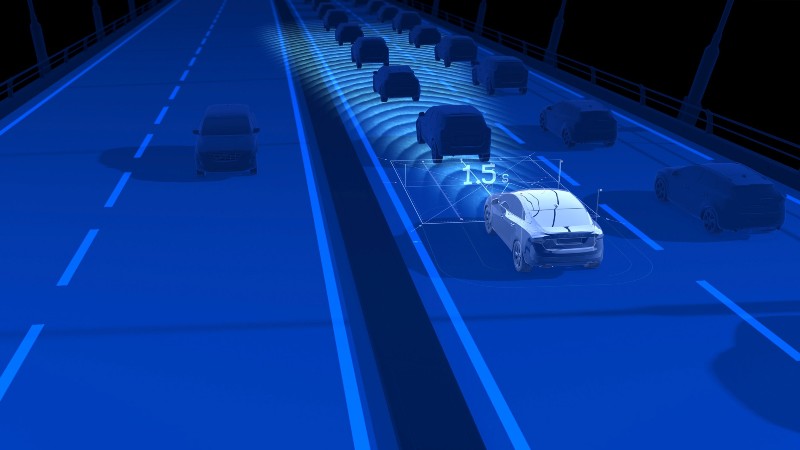

Queue warning systems are put in place to warn of upcoming work zones, slower zones, areas that commonly cause bottlenecking, or areas that are difficult to traverse due to limited visibility. The setup for a queue warning system typically comprises of a Portable Changeable Message Sign (PCMS) and sensors set up down the roadway to monitor traffic. When vehicles are slowing or stopped within range of the sensors, the PCMS displays warning messages to slow and warn motorists of the impending traffic.

The most significant advantage of these systems is that motorists are warned in advance of the actual slowing. There are certain things to look for that need to be met before a queue warning system is warranted. However, once these are met, the system will provide a warning for the motorists to avoid rear ending stopped traffic ahead.

There are things that need to be taken into consideration when setting up the system:

- Queue Length – These can vary a great deal from day to day. According to experts, the PCMS is ineffective if placed more than a mile from the traffic zone.

- Terrain concerns may create problems for motorists due to lack of visibility, which can cause emergency stopping and shortening reaction times significantly.

- Crossroads are known to cause issues for the main road, which can cause backups onto ramps, intersections, or other congestion areas.

How These Systems Help

Motorists are able to anticipate approaching situations of emergency traffic, including heavy braking and slowdowns, erratic driver behavior, and reduce or remove any collisions due to the queue. The Federal Highway Association stated in 2015 that queue warning systems could limit rear end accidents and other severe crashes by around 45%. A number like that shows how much of a difference the queue warning system makes in safety improvements for both road working crews and the motorists traveling through the work zone.

By monitoring the speed of vehicle speeds along the parts of the roadway that are causing the most significant concerns, the queue warning system can track and update any pertinent information to the PCMS systems. When oncoming drivers see the portable changeable message signs, they know what to anticipate in the road ahead, making the overall traffic flow more safely.

Permanent installations are necessary for specific situations. These permanent installations use different sensor systems than temporary queue warning systems. Sensors like inductive loop microwaves, video detection, and Doppler radar are frequently used to track the speed of traffic. Areas that are running into congestion at certain times every day are great candidates for these types of permanent installations.

Frequently used in highway work areas, the primary purpose of these warning systems is to ensure the motorists are well informed and ready to react to any situations in the road ahead. Reducing collisions and keeping highway workers safe makes using these systems a no brainer. Working to make the highways flowing smoothly and safely is something we can all get behind. The driving force behind queue warning systems is the proven safety record that shows more motorists are avoiding construction zone accidents than ever before when these systems are put in place.

Reduce Congestion with a Queue Warning System

If you would like to learn more about how you can use a queue warning system to great effect in your city, contact us at Worksafe Traffic Control Industries to speak with a knowledgeable member of our staff today.